Kettle charcoal grills have become an integral part of backyard barbecues and outdoor cooking experiences. These versatile cooking appliances are known for their smoky flavors and ability to sear food to perfection. Have you ever wondered about the manufacturing process that brings these grills from the factory to your backyard? In this article, we will take a deep dive into the fascinating journey of how kettle charcoal grills are manufactured, step by step.

Before we delve into the manufacturing process, let's briefly explore the history and evolution of kettle charcoal grills. The kettle design, with its iconic round shape and dome lid, was first introduced by George Stephen in the early 1950s. Stephen, a welder at Weber Brothers Metal Works, was inspired to create a grill that would allow for better temperature control and heat retention. This revolutionary design quickly gained popularity, and the kettle charcoal grill was born.

To ensure durability and heat resistance, kettle charcoal grills are primarily constructed using high-quality steel. Steel is an ideal material for grills as it can withstand high temperatures and provides excellent heat distribution. The body, lid, and cooking grates of kettle grills are typically made from steel, which is both sturdy and long-lasting.

To enhance the longevity and aesthetic appeal of kettle grills, many manufacturers apply a porcelain enamel coating to the steel components. This coating not only provides a smooth and glossy finish but also acts as a protective layer against rust and corrosion. The porcelain enamel coating also makes cleaning the grill easier, as food particles are less likely to stick to the surface.

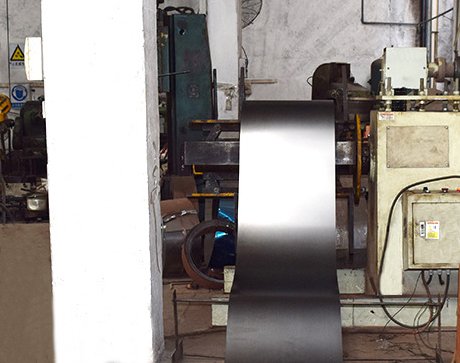

The manufacturing process of kettle charcoal grills begins with sheet metal fabrication. Large sheets of steel are cut into precise shapes using industrial cutting machines. These cut pieces form the main body, lid, and other components of the grill.

When it comes to manufacturing kettle charcoal grills, precision is key. The first step in the process involves cutting the large sheets of steel into precise shapes that will form the main body and lid of the grill. Advanced cutting techniques are employed to ensure accuracy and consistency in the dimensions of the components.

One of the commonly used cutting techniques is laser cutting. This method utilizes a high-powered laser beam to precisely cut through the steel sheets. The laser beam is controlled by computer programs, allowing for intricate designs and precise cuts. Laser cutting offers several advantages, including clean edges, minimal material wastage, and the ability to cut complex shapes with ease.

Once the steel sheets have been accurately cut, they are formed into the main body and lid of the kettle charcoal grill. Then process the flat sheets into the iconic round kettle shape.

The forming process typically utilizes hydraulic or mechanical presses. The cut steel pieces are placed in the press and subjected to controlled pressure, which gradually bends and shapes the material. The pressing operation ensures that the components take on the desired curvature and maintain structural integrity.

To achieve the characteristic domed shape of the lid, a separate forming process is employed. The flat sheet of steel is carefully shaped using specialized tools and dies, which create the gentle curve that allows for optimal heat circulation and retention. The lid is an essential component of the kettle grill, as it helps trap the heat and smoke, resulting in deliciously flavored food.

Once the main body and lid have been formed, they undergo further finishing processes, such as deburring and polishing. Deburring removes any sharp edges or rough surfaces, ensuring a safe and smooth finish. Polishing enhances the appearance of the components, giving them a sleek and appealing look.

The precision cutting techniques and meticulous forming process are vital steps in the manufacturing process of kettle charcoal grills. These processes ensure that the components are accurately shaped and crafted to meet the high standards of quality and performance that customers expect from these grills.

With the main body and lid formed, the manufacturing process moves forward to the next stages, including welding and assembly, where the various components are joined together to create a complete kettle charcoal grill ready for use.

Once the sheet metal finish the cutting, then punching the holes by stamping equipment, after that, they are welded it with accessories together to form the main body and lid of the kettle charcoal grill. Skilled welders use advanced welding techniques to ensure strong and secure joints. After welding, the assembled parts are inspected for quality control.

To protect the steel components from rust and corrosion, a porcelain enamel coating is applied. The coating process involves spraying or dipping the parts into a liquid enamel mixture, which is then baked at high temperatures. This process creates a durable and attractive finish.

To enhance the cooking performance of kettle grills, manufacturers incorporate heat shields and vents into the design. Heat shields are installed between the charcoal and the cooking grate to prevent direct heat exposure to the food. Vents, typically located on the lid and the bottom of the grill, allow for precise temperature control by regulating airflow.

Handles, cooking grates, and other accessories are attached to the kettle grill during this stage of the manufacturing process.

Choosing Heat-Resistant Handle Materials

Attaching Cooking Grates and Accessories

Once all the components are assembled and the grill is fully equipped, it goes through a thorough quality assurance process. This involves inspecting each grill for any manufacturing defects, ensuring all parts are functioning correctly, and conducting performance tests. Any necessary adjustments or repairs are made at this stage to ensure that only top-quality grills reach the market.

After passing the quality assurance tests, the kettle charcoal grills are packaged and prepared for distribution. The grills are carefully packed to prevent any damage during transportation. Depending on the manufacturer and distribution channels, the grills may be shipped to retail stores, online marketplaces, or directly to customers' homes. The availability of kettle charcoal grills in the market allows enthusiasts to bring the joy of outdoor grilling to their own backyards.

1. How long does the manufacturing process of kettle charcoal grills typically take?

The manufacturing process of kettle charcoal grills varies depending on the complexity of the design and the production capacity of the manufacturer. On average, it can take anywhere from 30 days to 45 days to complete the entire process for one container.

2. Are kettle charcoal grills suitable for beginners?

Absolutely! Kettle charcoal grills are often recommended for beginners due to their ease of use and versatility. With proper guidance and a few basic grilling techniques, anyone can master the art of cooking on a kettle grill.

3. Can kettle charcoal grills be used for smoking food?

Yes, kettle charcoal grills can be used for smoking food. By using indirect grilling methods and adding wood chips or chunks to the charcoal, you can achieve that delicious smoky flavor in your grilled dishes.

4. Are there any safety precautions to consider while using a kettle charcoal grill?

While using a kettle charcoal grill, it is important to follow proper safety precautions. This includes keeping the grill a safe distance from flammable materials, using heat-resistant gloves when handling hot parts, and never leaving the grill unattended while in use.

5. How can I maintain and clean my kettle charcoal grill?

To maintain your kettle charcoal grill, it is recommended to clean the cooking grates after each use, remove ash from the charcoal chamber regularly, and inspect the grill for any signs of wear or damage. Additionally, storing the grill in a dry and covered area when not in use can help prolong its lifespan.

6. Can I use different types of charcoal in a kettle grill?

Yes, you can use various types of charcoal in a kettle grill, including briquettes and lump charcoal. Each type of charcoal offers a slightly different flavor profile, so feel free to experiment and find your preferred choice.

The manufacturing process of kettle charcoal grills is a complex and meticulous journey that involves cutting-edge techniques, quality control measures, and a passion for outdoor cooking. From the initial fabrication of sheet metal components to the final packaging and distribution, every step is crucial in creating a high-quality grill that can withstand the test of time.

So, the next time you fire up your kettle charcoal grill in your backyard, take a moment to appreciate the craftsmanship and expertise that went into its creation. Whether you're a seasoned grill master or a beginner, these grills provide an excellent platform to unleash your culinary creativity and enjoy the flavors of outdoor cooking.

With their sturdy construction, precise temperature control, and unmistakable smoky flavors, kettle charcoal grills have become a beloved staple for backyard barbecues, picnics, and outdoor gatherings. From searing steaks to slow-cooking tender ribs, these grills offer endless possibilities for culinary delights.

In conclusion, the manufacturing process of kettle charcoal grills involves a careful combination of craftsmanship, quality materials, and attention to detail. From the initial fabrication of steel components to the application of porcelain enamel coating and the addition of essential features like heat shields and vents, each step contributes to the production of a reliable and high-performance grill.

Whether you're a grilling enthusiast or someone who simply enjoys the smoky aromas and mouthwatering flavors of outdoor cooking, a kettle charcoal grill is an investment worth considering. So, gather your family and friends, fire up the grill, and create unforgettable memories as you savor the delicious meals prepared on your very own kettle charcoal grill.

Looking for a custom kettle charcoal grill for your business? or wholesale kettle grill for your market? Contact us to learn more.