The process of developing and manufacturing a new BBQ grill in China can be complex and challenging. However, by following a few key steps, the process can be streamlined and made much easier. In this blog post, we'll take a look at how to develop and manufacture a new BBQ grill in China, from start to finish. We'll also dispel some myths about sourcing products from China, and show you why working with Chinese manufacturers can be a great option for your business. So let's get started!

A barbeque grill is a device that cooks food in outdoor. This can either be done by gas grills which use natural gas or propane, or charcoal/wood smoker/grills which use lit coals or wood. There are many different types of BBQ grills available on the market today and it’s important to do your research in order to choose the right one for you. With this guide, we hope that you now feel confident enough to begin mass production of your very own BBQ grill!

Developing a new barbecue grill concept can be an exciting endeavor that has the potential to impact the industry in a meaningful way.

If your idea involves a unique design or construction of grills, it is important to partner with a manufacturer who has all the necessary components for production and understands the regulatory environment. With proper planning, consideration of materials, and research into safety requirements, you may turn your idea into a product that people will love.

Understanding your target audience and their needs is crucial in developing the most successful product. Once you have taken these steps, work with an experienced team of engineers to bring your vision to life.

Suggestion A: If you're not confident about a product's potential success or if you don't want to spend too much money upfront, focus on lower-cost items or not larger size product in general.

Because all of bbq grill, smoker or fire pit products need to open full set molds. and is easily cost about USD5,000.00-USD10,000 up for mold. The larger the size of bbq products, the mold fee are more expensive.

Suggestion B: use some of your current bbq grill parst for your new product. It can save mold fee.

If you want to save on the mold fee for your new BBQ grill, consider using some of the parts from your existing product. This can be a great way to reduce costs while still ensuring that the new product meets all safety and quality standards.

In addition, working with an experienced manufacturer can help you understand which parts are safe to use and which ones need to be updated or replaced in order to create a safe and reliable product.

Suggestion C: Improve your current bbq product, make it better function and cheaper to produce.

Making an existing BBQ grill product better and cheaper to produce is a great way to get ahead of the competition in the marketplace.

Start by researching the current market trends and seeing what other manufacturers are offering in terms of features, materials, and price points. Once you have identified potential areas for improvement, look into ways to reduce costs.

Once you have your idea, it is important to use the feedback from existing users of similar products to improve upon the design and shape.

You can also research manufacturers that are producing a product similar to what you are trying to develop, as they may be able to provide insight into how their process works.

Finally, consider any possible upgrades or improvements that can be made in order to make the new product better than what’s currently available.

When it comes to sourcing and manufacturing, China is a great place to start. Chinese manufacturers are experienced and reliable, and can often provide lower-cost solutions that are of good quality.

To get a better understanding of the barbecue grills currently on your market, it is important to carry out in-depth market research. This will involve observing current trends and discovering what consumers like and don't like about them. Talking directly to users of the products can be a valuable source of insight, as well as looking into online reviews by customers.

Gathering this kind of information will provide useful direction while designing better products that meet customers' needs and expectations.

Finding the right factory to develop and manufacture a product can be a daunting task. However, with careful research and due diligence, it is possible to find a partner that is the perfect fit.

For example, consider compatibility with business goals, size of the operation, production capacity, machinery and equipment availability, material sourcing and cost assessment. Additionally, inquire about cost of services, timeline for completion of projects, any technical or design assistance offered and customer service quality.

Pay close attention to product samples, quality control standards, delivery times, certifications, production capabilities and price points.

Partnering with an experienced factory will help ensure high-quality results quickly and efficiently.

Estimating the cost of the whole BBQ grill project will depend on a number of factors, such as the type and complexity of the design, the materials needed for production, any regulatory requirements that need to be met, and more.

If you are working with an experienced manufacturer, they should be able to provide you with an estimated cost for your project.

Cost for design: including handmade cost, 3D printing cost, design drawing cost (there are no design drawing charge if you pay mold fee to factory)

Mold fee for factory: the mold fee depending on your design and product size. You could make a sample by handmade if you can’t make sure the product shape. But it depends on the product design whether it is suitable handmade. You could contact us to check your product whether it is suitable handmade.

Testing cost: check carefully which testing or certificate is mandatory. Like CE, FDA, LFGB etc.

Sample cost: The factory will offer 1-2pcs samples if you pay mold fee. You could pay sample fee if you want to made it by handmade. (The sample fee about USD120.00-USD230.00, depending on your bbq grill design.)

Express cost: Pay a small express fee to confirm sample and the quality.

Patent cost: The patent process can be costly, so if you have the budget for it, you should apply for a PCT. But typically, a lot of company will get a shield in their Country of Sale first, and then add more countries as sales increase.

Product unit price: Factor in materials and construction: The materials used to construct a grill can also impact its price. Grills made of stainless steel or other high-quality materials will generally cost higher. Charcoal grill generally made in carbon steel.

And include any additional features: BBQ grills can come with a variety of additional features, such as built-in thermometers, rotisserie attachments, and side burners. These features can add to the overall cost of the grill.

Packing cost: Standard package is one piece pack in one carton, because it will be distributed directly from the warehouse to the consumer via courier or shop.

The costs will depend on the size of the product, design, requirements (brown carton or color box) and quantity ordered, but typically it is around 1.2-2.5 USD per unit for packing cost.

Note the outer carton should be test the Drop test (ISTA 1A) to ensure there are no damage for your product during delivery if you needed.

Rate of defect product: every one want to buy 100% perfect finished product from factory, but there is no one can control the products are in 100% of pass. We can add the specific rate of defect product to control our cost of production.

Shipping cost: Choose the best way to transport your goods and add the freight into the product unit price.

A lot of customer transport the goods by sea. because it is not expensive. Also, you need to calculate it can load how many pcs bbq grill into one container. For example, it can load 260 pcs (22inch charcoal kettle grill) into 20FT container, shipping fee is USD900.00. Then the freight is USD3.462 for each one. (The charges are not including costs of your local)

Note that buy insurance for your goods when you ship it. Reduce risk and the loss to the minimum.

Warehouse cost: You could storage more bbq grills and consider bringing more goods in one time for cheaper freight expenses if you have a warehouse at a reasonable rate. So that you could sell it good during peak season. BBQ products peak season is May to August. (Our customers place order in August to April of next year.) Then ask the factory to send it in demand in low season.

Estimate your marketing cost, like the SNS advertising, Google ad, Amazon, offline advertising etc. and add it into your product unit price.

When it comes to the quality of your BBQ grill, you want nothing short of perfection. That's why working with the factory to develop a sample that satisfies your standards is essential.

Whether it's adjusting the design, testing different materials, or ensuring certain performance standards are met, engaging with the factory ensures that the final product meets your needs and excites your customers.

There are several steps involved in the manufacturing process for BBQ grills. Here is a general overview of the process:

Design: The first step in manufacturing a BBQ grill is to design the product. This may involve creating detailed drawings and specifications for the grill, including its size, shape, materials, and features.

Material selection and sourcing: The next step is to select the materials that will be used to manufacture the grill. This may include metal for the body (fire bowl, lid and leg etc) and grill grates, plastic for the handles and wheels, and other components such as burners and thermometers.

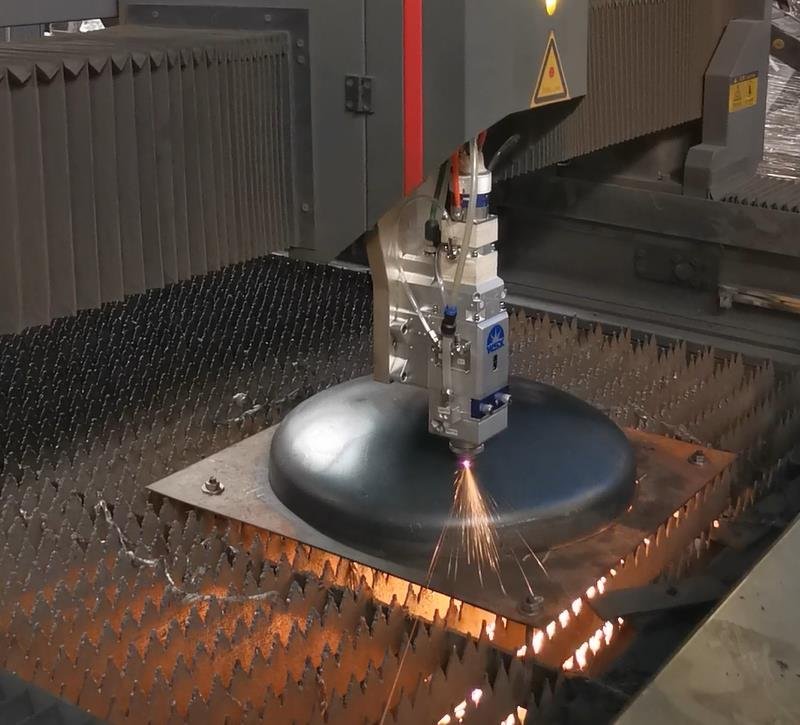

Cutting and forming: Once the materials have been selected, they are cut to the correct size and shape using machines such as lasers or cutting machine. The metal parts are then typically bent or formed into their final shape using tensile machine and other forming equipment.

Welding and assembly: The various parts of the grill are then welded or fastened together to form the complete grill. This may involve assembling the body of the grill, attaching the grill grates, and attaching any additional components such as burners or side tables.

Finishing: After the grill has been assembled, it is typically finished with a coating such as paint, porcelain-enameled or powder coating to protect it from the elements.

Testing: Before the grill is shipped to customers, it is typically tested to ensure that it meets all of the required specifications and is safe for use. This may include testing for things like temperature control, ignition, and overall durability.

Overall, the manufacturing process for BBQ grills involves a combination of machine work, assembly, and testing to produce a high-quality product that is ready for use.

Quality assurance starts with consultation and collaboration, and we look forward to getting started as soon as possible.

Be sure to provide the factory with all of the necessary specifications, including the size and style of the packaging, the materials to be used, and any additional features or customization that you have requested.

Test the packaging: Before you start using the customized BBQ grill packaging in your business, it's a good idea to test it to make sure it meets your needs and expectations. This may involve simulating real-world shipping and handling conditions to see how the packaging holds up.

I once wrote an in-depth article about how to choose package for bbq grill product. You can take it as your reference.

With the design ready, you could place a trial order with the factory, so that test the market. After that, beginning mass production of your new BBQ grills is the logical next step. Not only will this ensure a saturated market presence, it will also reduce manufacturing costs by taking advantage of economies of scale.

Our experienced team has vast knowledge on best practices to ensure that your production process remains cost effective and efficient while still delivering quality BBQ grills that meet consumer standards. Working with us would be a smart investment and could potentially result in quicker returns on your project.

In order for your new BBQ grill to be legally sold in your country, it must meet all applicable safety standards and regulations of the country government.

Different countries have different requirements for food safety and other related products, so it is important to know the rules and regulations that apply to the country where your product will be sold. Certification can be complicated, so it is in your best interest to consult with an experienced professional who specializes in this field.

Also, you could ask our sales team, we have worked with many countries on the bbq products. they will advise you what certificate you need.

Once you have partnered with a reliable supplier, you need to figure out how to transport and deliver the new BBQ grill. Depending on the size of your product, you can ship it via land, air or sea.

Establishing an agreement with a logistics provider is essential when working with manufacturers in China, as they will be able to provide you with the best rates and delivery times. Additionally, having a good understanding of customs regulations and paperwork requirements is necessary to ensure that your product arrives safely.

Conclusion

Developing and manufacturing a new BBQ grill in China can be both exciting and challenging, but with the right research, planning, and support, it is possible to get your idea off the ground. By researching market trends, understanding customer needs.